You imagine your dream home to be a beautiful, safe, and comfortable place. With the steady rise in energy costs and the effects of climate change, it's also a smart decision to make sure it's environmentally friendly and energy-efficient. Thanks to today's modern materials, your next home can be all this and more.

LOWER ENERGY BILLS

Thermal mass walls create more efficient homes that can reduce heating and cooling cost by up to 60% a year.

FIRE PROTECTION

Non-toxic, fire retardant expanded polystyrene foam provides a fire protection rating of up to 4 hours.

COMFORTABLE CLIMATE

Improved ventilation for healthier indoor air quality and an environment that's less susceptible to mold.

One Material, Limitless Benefits

Wind resistance of up to 250 mph (402 kph), equivalent to an F4 tornado.

Steel-reinforced solid concrete cores ranging from 4 inches to 12 inches provide superior strength and safety compared to wood.

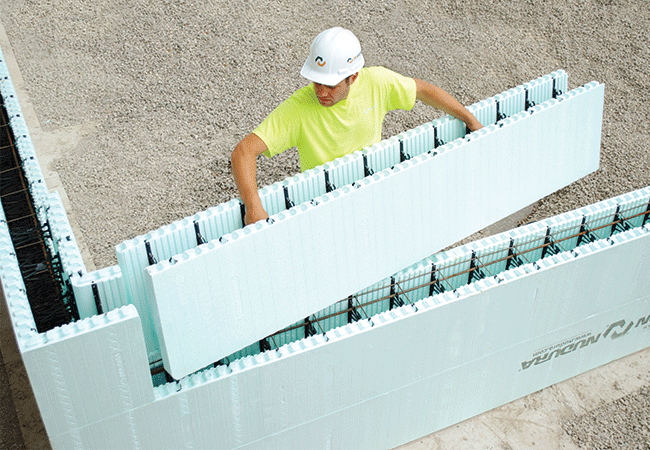

Flat packed and easy to install, Nudura ICFs require less labor to install, which can help lower your overall construction costs.

Your home is less likely to contain cold areas as the insulation is continuous around the entire house.

Concrete forms require less maintenance over time, saving you the expense and effort of continuous upkeep.

Our ICFs are made from 100% recycled polypropylene, reducing waste and your home's carbon footprint. By choosing an alternative to the wood you're also helping the planet, as wood framing contributes to global deforestation.

The Anatomy of Comfort

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Pellentesque rutrum ligula ut nunc varius bibendum nec eu massa. Morbi non dolor eu neque eleifend vulputate in quis lorem. Suspendisse potenti. Donec cursus tellus a justo tempus, ut condimentum velit vulputate.

-

How do I fasten baseboards in a Nudura Insulated Concrete Form House?

The best way is to rip a plywood strip to, 2 1/2" wide and screw it in place to the webs along all the walls. Fasten these strips at every fourth web. Now the drywall contractors can set their drywall on top of it, and will cut their top sheets accordingly to suit this height. The result is you have full wood fastening for nails along the complete wall surface and the plywood is guaranteed to be covered by the baseboard.

-

How do you attach siding, drywall or other finishes to Nudura Insulated Concrete Forms?

The Nudura form unit has a fastening strip located every 8” (200mm) on center. These fastening strips are continuous up the full height of the form unit and have a patented mechanism that interlocks one fastening strip to the one below it or above it. These fastening strips are indicated on the surface of the form by a diamond pattern. They are 1 ½” wide and have a higher pull-out strength than a dimensional stud. Different types of cladding will have different installation procedures.

Watch Nudura's Tech Talk video on attaching finishes to a Nudura Insulated Concrete Form Wall.

-

How do I find a Nudura trained Installer?

The distributor for your area will be able to provide you with a list of Nudura trained installers for your area.

-

How is my Distributor different than my Nudura Insulated Concrete Form Installer?

Your Nudura Distributor is the support center for your project and your Installer is the one who is the one who will be on-site building your home. Should you need to find a Nudura trained installer (contractor), architect or engineer, your distributor will provide you with a list of professionals that are familiar or have used Nudura products and accessories. Your Nudura Distributor is also responsible for the sales and technical support for your Nudura Installer (contractor) throughout your entire project being built with Nudura Insulated Concrete Forms. Once you have chosen your Nudura Installer for your project, you may have little or no contact with your Distributor as you will be dealing with your Installer.

Continue Exploring...

CONTACT US

We’re committed to supporting homeowners and design professionals who are interested in or use our products. We’re always happy to help and provide more information.